Drilling Chip Control & Cutting Fluid

Drilling chip control and cutting fluid

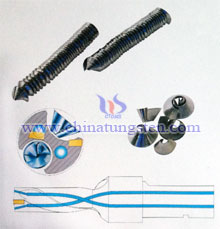

Drilling chip control and cutting fluid is an important factor in the drilling. Generate suitable drilling chip shape and size as well as to rule out any drilling operation is critical. In this regard, if there is no satisfactory performance, any drill will be due to drilling cuttings will be clogged in the hole in a short time to stop cutting. The modern drill high cutting speed and high feed can be effective chip evacuation, through the use of cutting fluids become possible.

Drilling chip formation is influenced by workpiece material, tool geometry, cutting speed, feed, and to some extent, cutting fluid selection. In general, high feed, low cutting speed will produce short drilling swarf. If the drilling cutting can be stably outflow, the length and shape of drilling cuttings can be said to be acceptable. Most of the shallow hole drill with two flutes. The use of modern machine tools and drilling tools, the coolant holes through the drill head to provide cutting fluid, can effectively complete chip removal. Cutting, the cutting fluid is ejected from the drill's top, and can not only lubricate the drill bit, and the cutting fluid of the drilling cuttings through the outflow of flutes.

| Drilling Chip Formation, Chip Removal, Cutting Fluid Supply |

|

Modern carbide drill flutes with high metal removal rate and density. Under high pressure, it is to discharge drilling chip through the inside cutting fluid. The desired pressure (Mpa), and the flow rate (liters / min) depends mainly on pore size, but also by the impact of the cutting conditions and the workpiece material.

The cutting fluid used in metal cutting, grinding and machining process used to cool and lubricate the tool and workpiece industrial liquid, cutting fluid by a variety of super functional additives through scientific complex compatibility made, along with good cooling performance, lubricating properties, rust performance characteristics. Cutting fluid through the internal supply, due to the effect of centrifugal force will cause the pressure reduction in rotary drilling requirements are higher than the non-rotating drill cutting fluid pressure. This does not have to be compensated with a high cutting fluid pressures can be used flow compensator. However, for non-rotating drilling and the use of the outer cutting fluid, it is also required to consider a drop in pressure within the transmission system.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com