Drilling Cutting Force & Power

The drilling cutting force and drilling power

Machining holes need a certain amount of energy (drilling power). The drilling process the drill bit penetrate the workpiece in order to remove the metal, drilling cutting force acting on the drill bit. Thus, drilling has some drilling power requirements. Start a discussion of this issue, we must first know the relevant drilling power workpiece material requirements, when calculated, the need to determine the material referred to specific drilling cutting force is much.

Drilling power in addition to material factors, drilling power (Pc) and diameter, feed rate and cutting speed. Drilling power required approximate formula can be used to check the machine can meet the needs of the drilling power. For modern machine tools, drilling most of the medium-diameter hole is no problem, but for large diameter holes have several times the aperture depth, still need to check the drilling power.

Torque for the large diameter drilling step, especially for the sets of holes to consider the drill cutting bear the total drilling torque, Nm is the torque value (Mc) is another RMS. Feed, diameter, materials affecting the major factor of the torque value. The torque is the sum of the torque on each cutting edge and is the tangential force and the product of the radius to the diameter of the center distance.

| Feed Force & Torque |

|

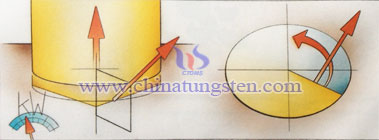

The feed force from the drilling point of view, to the N units of the feed force (Ff) is the most important factor. This is the barrier material when the axial force acting on the drill bit. To ensure that the power and the spindle of the spindle drilling strength to meet the requirements of the drilling step is very important, therefore, need to be considered too large feed force will affect the quality of the hole, the reliability of the drill bit, and so that the machine is stopped. On the other hand, from the viewpoint of productivity, sufficient feed force, the drilling action is important. The feed force is related with the diameter of the drill, the feed and the cutting material. A cutting edge angle of the drill bit (kr), also affect drilling cutting force.

| Apex Angle & Cutting Edge Angle |

|

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com