Content Crumbs Taps

Content crumbs taps features

The use of heavy machinery, generators, diesel engines, steam turbine materials are generally of higher strength materials; processing in the above high-precision, low roughness, most of the big pitch threaded hole blind hole, the processing conditions are harsh. Previously described a variety of tap processing different problem exists. Example: ordinary straight flute tap the chip space is limited, and is likely to cause the chip clogging turn tap chipping, breakage or workpiece processing thread damage. The helical grooves tap originally can be processed, but the large-diameter helical groove taps more difficult to manufacture. In addition, due to the relationship of the outside chip to tap in return, to squeeze into workpiece processing thread surface, may cause the workpiece processing thread is destroyed because extrusion. Once threaded failed to produce a lot of repair work and result in substantial costs.

A new capacity of debris the way - Content crumbs proposed content crumbs tap also able to appear to be shipped. The main features of the structure of the content crumbs tap: the processing capacity of storage chip crumbs hole in the center of the tap, in the process flutes in the tap end and has a certain edge inclination. After the tap cutting cone, as for the correction, supporting and guiding the complete shape thread. When used together form the front corner and edge inclination beveled diversion effect, the chip guide people to tap the center of the chip hole, the chip and the machined threaded surface isolate. Workpiece processing thread is no longer subject to the chip impact, and extrusion screed role as a correction of complete thread greatly improved the surface quality of the workpiece thread, thread accuracy and roughness guaranteed. Content crumbs tap is threaded divided into three parts, namely the cutting portion, the correction portion and the guide portion. Cutting portion on the cutting cone, the whole thread truncate has posterior horn, play mainly cutting action. Correction portion of the thread shape is a complete non-grooved or slotted screw. These parts of the thread without posterior horn plays have been cutting forming screw extrusion the screed of correction role. The guide portion of the thread is the shape integrity slotted threaded, but the pitch diameter is smaller than the correction section. This part of the thread only play a guiding role to ensure that tap feed properly, smooth.

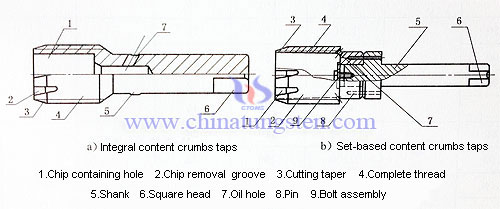

The content crumbs tap in addition to cutting cone shape complete the thread. Tap fully into the workpiece, cooling and lubricating fluid barrier, can not enter the workpiece, the cutting conditions deteriorate. To improve this situation, the general Taps on processing two or more direct chip hole hole (pictured).

| Contents Crumbs Taps Structure |

|

Content crumbs tap because of these characteristics, particularly suitable for precision machining, low roughness, the large diameter and deep threaded blind hole.

Machining centers, CNC machine tools, extensive use and provides excellent conditions for the use of the content crumbs tap. Content crumbs tap more and more into the various types of processing industry.

Content crumbs tap into the overall style and suite-style, suite-style general greater than M64 thread size. The overall content crumbs tap from the chip hole, flutes, cutting cone, complete shape correction thread-oriented threaded shank hole. Nested crumbs tap the working portion and the shank portion are separated, and the working portion is the same as the overall content of crumbs tap. The working portion and the shank rely bolted together, and power is transmitted simultaneously with the pins. Work due to the cutting force increases or for other reasons too large torque, the pin is cut. The taps working portion and the shank portion is still intact, can be reused, and the threaded hole in the workpiece is not caused scrapped. The nested content crumbs Taps different structure due to the manufacturer or may not be identical.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com