Solid Cemented Carbide Taps

Characteristics of solid cemented carbide taps

cemented carbide material characteristics, cemented carbide taps unique manufacturing process characteristics and the characteristics of the design parameters, the use of advanced coating technology, the basic performance characteristics of cemented carbide taps.

1. High durability

Machining cast iron, aluminum and other materials, the equivalent of high-speed steel cone 20 to 50 times its durability. This is carbide hardness (HV30 up to 1850 or more, equivalent 83HRC above), good hot hardness (up to 900 ° C to 1000 ° C), excellent wear resistance and other factors.

2. The high cutting efficiency

Machining cast iron, aluminum and other materials, the cutting speed is equivalent to high-speed wire cone 3 to 6 times, the use of special equipment accessories, aluminum alloy tapping speed equivalent to 15 times the speed of high-speed wire cone tapping.

3.Processing of the threaded bore, high precision, and dimensional consistency

Solid cemented carbide taps in the entire production process, the milling process, completely full grinding process to ensure the accuracy of the geometric parameters of the tap; Solid cemented carbide taps anti-wear ability, processing screw holes size, tooth type angle consistency, laid the foundation for the processing of high-precision screw holes.

4. High rigidity

The elastic modulus of the solid cemented carbide taps up to 600Gpa, equivalent to about three times as high speed just tap, Solid cemented carbide taps rigidity equivalent to approximately three times the high-speed wire cone. The farther from the machine tool spindle in the processing of the screw holes (tap overhang longer), the elastic deformation of the former than the latter is about 2 times lower, and the processing of the screw hole difficult eccentric, and the position accuracy is better.

5. Tapping competent difficult to machine materials

In recent years, the world-famous tap manufacturers launched the distinctive characteristics of solid cemented carbide taps to expand the application range of solid cemented carbide taps. The high hardness of quenched and tempered steel (50HRC 60HRC), thermosetting plastics, has targeted solutions. The basic features are: cemented carbide substrate material with ultrafine particles (WC-size 0.4μm) HV30 ≥ 1700, the flexural strength of TRS ≥ 3500N/mm2 composite multilayer coatings, cemented carbide taps the unique structure and parameters, and enhance the strength thereof.

6. Can achieve high-speed tapping

Specifically for the design of equipment for synchronous feed solid cemented carbide taps, to achieve high-speed tapping. When machining aluminum, the cutting lines the speed υc up to 300m/min.

7. Not suitable for good toughness, the processing of the material of the breaker difficult

Processing good toughness of the material, cemented carbide taps worn to a certain extent, the main cutting edge presents a trace of serrations (20 times magnification can be clearly found), the cemented carbide taps of the chip breaking capability becomes weak, swarf and easy winding taps, since the hard brittle than high-speed steel, alloy increase fracture risk taps.

8. The accuracy of the machine tool system, the workpiece clamping accuracy requirements

(1) Of the basic requirements of the machine tool

Machine tool spindle run out less than 0.005mm, steady work.

(2) The accuracy requirements of the loaded knife

Taps mounted on the tool on the system, the machine spindle run out less than 0.02mm.

(3) After the workpiece is clamped in the process may not shaking.

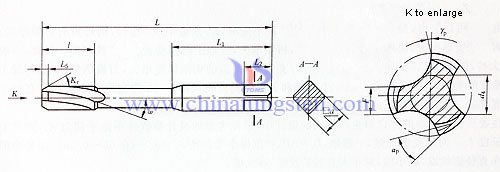

Cemented carbide taps structure of the form shown in Figure

| Cemented Carbide Taps Structure Form |

|

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com