Trapezoidal Thread Taps

Trapezoidal thread and trapezoidal thread taps

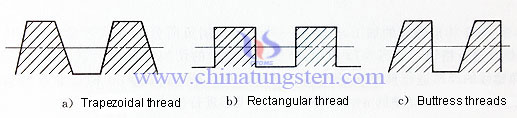

As the threads of power transmission, motion and displacement functions, depending on the tooth, rectangular threads, trapezoidal thread and zigzag thread of the points.

Rectangular threaded Figure b), its tooth shape is square, tooth type angle of 0 °, the highest transmission efficiency in the three threaded in, but the root low intensity and low driving accuracy. Precisely because of this, the rectangular thread not yet been standardized, and have been gradually replaced by the trapezoidal thread.

Serrated thread in Figure c), tooth-shaped asymmetrical, face flank angle of 3 ° Face flank angle of 30 ° (45 ° hydraulic press in our country serrated thread, its face flank angle 0°, the non-working face of the flank angle of 45 °. U.S. national thread serrated the Face flank angle of 7 °, the non face flank angle of 45 °). The Buttress comprehensive rectangular threaded high transmission efficiency and high the trapezoidal thread root strength advantage, but only for transmission of unidirectional power and movement occasions.

| Power Transmission of Three Kinds of Threads |

|

As of trapezoidal thread, tooth type angle of 30 ° (U.S. ACME trapezoidal thread, dental angle of 29 °), transmission efficiency is lower than the rectangle thread root strength neutral and, at the same time due to the process of the trapezoidal thread processing and measurement are more rectangular threaded convenient, so the first trapezoidal thread is used instead of the rectangular thread, is mainly used for the transmission of force and motion, mechanically generated transverse (linear) movement, is the most widely used one transmission thread.

| Trapezoidal Thread Teeth Type |

|

The trapezoidal threaded processing generally turning trapezoidal thread tap tapping method. Turning trapezoidal thread, due to the low production efficiency, and easy to ensure accuracy in single or small quantities only when used; widely used in mass production the trapezoidal thread Taps processing trapezoidal thread. Due to the trapezoidal thread pitch, tooth type angle is less, and thus it’s processing of cross-sectional area larger, tap thread machining with a trapezoidal thread, the feed amount of each of the cutter and the cut chips are large. Trapezoidal thread taps cutting load and cutting torque than ordinary thread taps much larger, if poorly designed, very easy to make the trapezoidal thread taps because of overload and broken. In order to avoid such accidents, and to prevent damage to the processing thread (workpiece), in addition to the trapezoidal thread pitch tap processing of a single branch, in most cases, the trapezoidal thread are used by the two / three / group even more support trapezoidal thread taps into groups taps processing. Branched group taps should be based on the size of the processing thread, accuracy requirements, and the nature of the material to be processed may be.

Since the trapezoidal thread tap cutting load than ordinary tap, therefore, under normal circumstances, only for the working diameter of 50mm or less, and a pitch of 6mm below trapezoidal thread (the most common Tr30 × 6), the branched group taps generally not more than three.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com