Spiral Fluted Taps

Spiral fluted taps trench spiral the tapping is able to effectively control the flow of the chip discharge; thereby avoiding the clogging caused a series of tapping puzzle. Widely used in all kinds of blind holes, threaded through hole machining portion and the workpiece, is an efficient internal thread processing of special tools. In addition, the oblique cutting spiral grooves are formed, spiral flute taps in the processing of stainless steel and other difficult-to-machine materials have a distinct advantage.

The form of spiral flute taps trench

Spiral fluted taps significant helical groove structure is characterized by its helical groove, and application characteristics are effective in controlling the chip discharge. So the main forms of trench, spiral flute taps are classified as follows:

a) The spiral groove cut in a the right spiral fluted taps. This spiral flute taps trench structure for a right spiral grooves, right hand thread. Used to be able to control the thread, using the processing dextrose swarf discharge tap shank to the helical groove, suitable for machining deep blind holes and with the screw holes of the recess notch processing, is the most widely used structure of helical grooves tap form. And spiral flute taps usually refers to spiral flute taps the backward chip removal structure.

b) The left spiral groove right to cut the spiral fluted taps. The spiral flute taps structure for the left spiral grooves, right hand thread. Means for processing handed internally threaded, in use be able to control chip is discharged to tap the front, suitable for the through screw hole machining, with the use of functions similar to the spiral fluted taps, but not identical. On the one hand because of the smaller the spiral fluted taps trench positive taper, resulting in the front end of the spiral fluted taps chip removal less space, especially the lack of control chips to screw holes center to discharge the functions, integrated former chip removal ability to less spiral point taps ; larger helix angle, on the other hand, but increase the axial component of the former chip removal, and bevel cutting more obvious, work greater angle before its processing viscous materials such as stainless steel, as well as with the concave the slot gap through screw holes, there is a certain value. Sometimes against certain workpiece, available to increase or reduce the spiral angle of spiral fluted taps as well as the approach of the number of grooves, to improve the processing quality of the through-screw holes, the effect may be better than the spiro tip taps, but higher costs.

c) Helical grooves left cut helical groove taps: This spiral flute taps trench for the left spiral groove, the left-handed thread. For processing left-handed internally threaded, in use be able to control chip is discharged to the tap shank, suitable for machining deep processing of the blind screw holes of the left-handed.

d) The right spiral grooves left to cut the spiral groove taps: Taps structure of such a spiral groove for a right spiral grooves left hand threads. Means for processing left-handed internally threaded, in use be able to control chip to tap the front discharge, applicable to the processing L pass threaded bore.

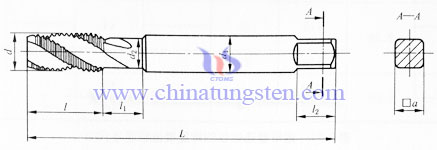

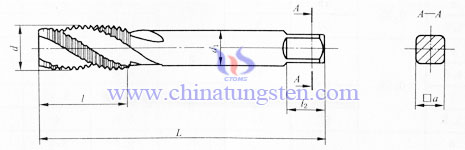

| Spiral Flute Taps Basic Structure |

|

| Nominal diameter Ф3 ~ Ф6 spiral flute taps crude shank with neck structure type. |

|

| Nominal diameter Ф7 ~ Ф33 spiral flute taps "shank" basic structure type. |

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com