cemented carbide reamers accuracy & surface roughness

Cemented carbide reamers the accuracy of the cutting edge and the surface of the machined surface roughness (Automotive parts processing)

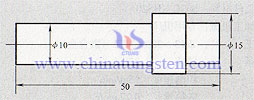

| Workpiece material:SCM4(HS35) | Parts diagram |

| Processing machinery: transformation machine tools |  |

| Tools:φ5x170TH10 | |

| Conditions: Rotation speed 500r/min Cutting speed 8m/min Feed rate 0.15mm/r Allowance 0.1mm/side Cutting fluid Use |

Results: leave a lot of traces of the processed surface, the performance is very uneven. Careful grinding of cemented carbide reamers, will improve the quality of the machined surface.

|

|

| Machined surface after machining of cemented carbide reamers with cutting gap | Then obtained after processing the surface of the hole to remove the notch of the cutting edge, with hardness above 600HRA gold drama abrasives of abrasive |

Summary: reduce cemented carbide reamers allowance; it seems that the problem can be solved. But then cutting edge has attachments, and the processed parts still have defective products. Closer inspection, cemented carbide reamers cut some notched. Take the appropriate measures in this regard (ie careful grinding of cemented carbide reamers), and right again to return to a stable state.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com