Cemented Carbide Reamers Allowance & Surface Roughness

Allowance and surface roughness with cemented carbide reamers (automotive parts hole machining)

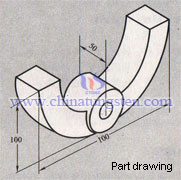

| Workpiece material:S55C(HS20) | Parts diagram |

| Processing Machinery: special machine tools |  |

| Tools: φ13x280xMT2 (micro-alloy) | |

| Conditions: rotation speed 370r/min Cutting speed 15m/min Feed rate 0.27mm/r Allowance below1.0~0.8mm→0.5mm |

The result: usually with a drill to open the prefabricated hole drilling process, and then hollow, then broaching. In order to improve production efficiency, the plan to drill after processing, the use of cemented carbide reamers finishing. However, using the brazing cemented carbide reamers are difficult to obtain the required machining accuracy; the size of the tolerance range is not stable. Left cemented carbide reamers allowance can be reduced to 0.5mm or less, the size of the hole can be restricted to within the allowable tolerance range.

|

| Roughened machined surface because of to the presence of attachments when cutting |

Summary: cemented carbide reamers are one of the cutting tools; the cemented carbide reamers processing effect that depends on the state of the prefabricated holes, so that is not too much. If the processing of pre-hole on the cutting edge, there are many attachments, it is impossible to obtain a predetermined size. Therefore, the requirements of the pre-hole left allowance should be small, and the size of the error should be small (to meet these requirements may be used carbide drills). There, then you can use the guide sleeve, cutting edge jitter 0.01mm allowance of 0.3mm, about processing tool grinding and then 900 holes.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com