Cemented Carbide Tool Nose Radius

Nose radius and machining surface to improve accuracy (finishing inside diameter of mechanical parts)

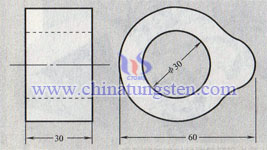

| Workpiece material:SCM-4(HS30) | Parts diagram |

| Processing machinery: turret lathe |  |

| Tools:Boring tool:6.35°x3.2 (TC2) | |

| Conditions: rotation speed570r/min Cutting speed270m/min Feed rate0.15mm/r Cutting depth3mm Cutting fluid (water-insoluble) |

Results: R0.4 corner radius becomes R1.2 nose radius knife life will be very different. The nose of the tool worn smooth, further increase the angle of the rear of the nose portion, the above phenomenon disappears.

| Good nose radius | Poor nose radius | Easily formed angle on nose radius example with hand ground |

|

|

|

Summary: In general, to improve the accuracy of the machined surface of the method is to: improve cutting speed; reduce the amount of feed; cutting fluid (oil); increase in chatter marks within the nose radius. Always happen in the width of each feed connection part will have glitches. Especially with the tip of the hand-grinding, look very smooth, but is actually a polygon, or the presence of eccentric. Combined with point or polygon angle at the tool tip, the cutting edge is prone to chipping, the machined surface burr special.

Want to get the surface roughness of the machined surface, select the appropriate corner radius is certainly very important, but the use of machine the grinding tool tip so that it is more important to be rounded in state.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com