Cutting Fluid Effect

Cutting fluid effect (outer periphery cutting of vehicle parts)

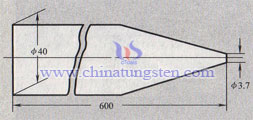

| Workpiece material:SS41(HS20) | Parts diagram |

| Processing machinery: automatic lathe |  |

| Tools:E22R—33TNPR331(TC2) | |

| Conditions: rotation speed 950r/min Cutting speed 120m/min Feed rate 0.15mm/r Cutting depth 1.5mm |

Result: no cutting fluid, general machining cutting edge chipping in 30 parts, machined surface glitches. If you use Cutting fluid, tool life can be extended to about 80 parts can be processed. The effect of the Cutting fluid is obvious.

Summary: cutting fluid effect - Cutting fluid cooling effect not only to prevent the rise of the workpiece material and tool temperatures, cutting fluid and also to prevent the lubricating effect of the friction of the workpiece material and tool behind. At this time, the cutting edge of the influence of these two effects, its rear wear and plastic deformation does not occur, and thus extend the life of the tool to the Cutting fluid.

As shown, if the different types of the material of the blade, cutting fluid, the amount of wear can also vary.

| The impact of the cutting fluid with materials of alloy ceramic class (TC2) | |

|

|

| The impact of the cutting fluid - only brush cutting liquid on the cutting edge, the cutting fluid supply is not sufficient, the cutting edge wear and thermal cracking occurs | The impact of cutting fluid - cutting fluid is sufficient, cutting edge wear hardly occurs, , but the avalanche phenomenon occurs in the melanocortin portion |

| Performance when using oil-based Cutting fluid (S20C turning test) | Performance when using water-soluble Cutting fluid performance (S20C turning test) |

|

|

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com.

sales@chinatungsten.com

sales@chinatungsten.com