Face Milling Cutter Applications

To obtain surface roughness below 6S with face mill (machine base)

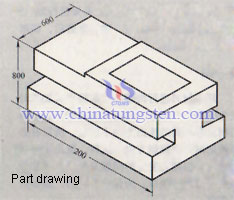

| Workpiece material:FC25(HS20) | Parts diagram |

| Processing machinery: Dragon Gate (paddle) milling machine |  |

| Tools: micro milling cutter TH10 | |

| Conditions: rotation speed130r/min Cutting speed 80m/min Feed rate 0.1mm/r Cutting depth 0.5mm |

Results: The usual practice is to cemented carbide milling on the front on the cutting edge machining plane (plat land), cemented carbide milling clamping on the machine, to be processed very difficult to 0.01mm below. However, if the use of micro cemented carbide milling, grinding, assembly as long as the cemented carbide milling Vice behind unflatness will be absorbed, the cemented carbide milling 's cutting edge will form an ideal arrangement, thereby enhancing hard the accuracy of the machined surface of cemented carbide milling cutter. And the assembly is relatively simple, can significantly improve the efficiency of the cemented carbide milling.

|

| The miniature cemented carbide milling of the surface roughness of the machined surface (on) is relatively small, and using a flat (bottom) a cutting edge will periodically undermine its gentle |

Summary: In order to improve the accuracy of the machining surface, in the front processing plane is the general practice, but because of the assembly with the bad unevenness and tilt occur during grinding can not be guaranteed to be able to achieve the accuracy requirements. Fillet micro cemented carbide milling use front-end, will be able to improve the machining accuracy.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com