Cemented Carbide Reamers Oil Supply & Surface Roughness

Cemented Carbide Reamers Oil Supply & Surface Roughness(automobile parts machining)

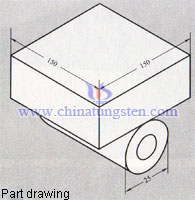

| Workpiece material:FC30(HS30) | Parts diagram |

| Processing machinery: transformation machine tools |  |

| Tools:φ16x280xMT2(Microalloy) | |

| Conditions: Rotation speed 900r/min Cutting speed 45m/min Feed rate 0.35mm/r Allowance 1.0mm/side Cutting fluid Use |

Results: plan to only use cemented carbide reamers finishing hole with the drill bit processing. Cemented carbide reamers processing chip clogging occurs. Finally, from the outlet side of lubricating the chip flow, solve this problem cemented carbide reamers processing.

|

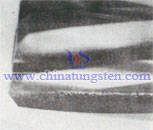

| Wear of the cutting edge due to lack of oil supply |

Summary: cemented carbide reamer processing, when its more than 10 times the diameter, the cutting length of the cemented carbide reamer hole will chip clogging occurs, this cemented carbide reamer the machining surface and dimensional accuracy are very big impact, so it is necessary to take measures to put the chips forcibly ejected. Using the barrel drill is one way, but the equipment involved. Finally, solve the problem by supplying oiling from the export side.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com